| 性能特点 |

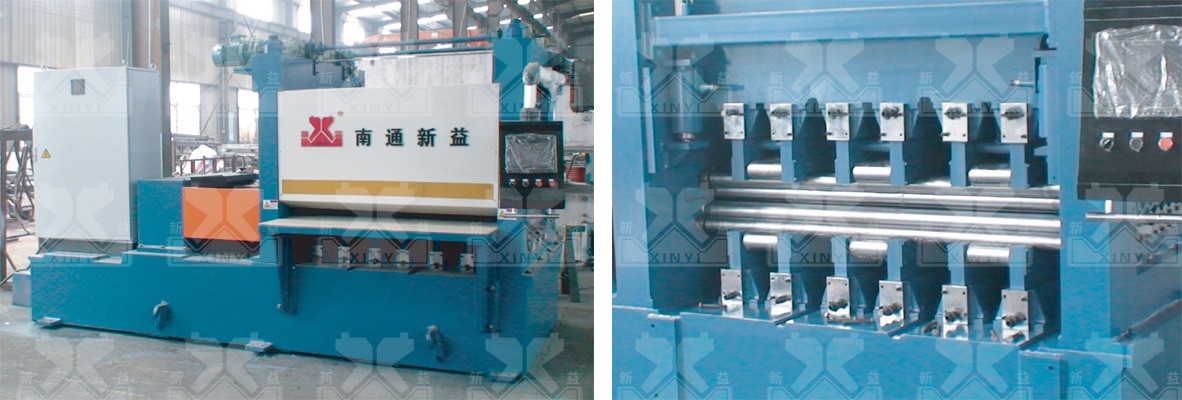

本机床是四重式校平机的升级机型。在上、下排校平工作辊与支撑辊(轮)之间各加装进一排中间辊,构成 上下各三重,共六重的组辊结构。通过中间辊的过渡,支撑辊{轮)的支撑力不直接作用于工作辊,避免了四 重式校平机工作时,在敏感材料表面留下支撑辊{轮)压痕的现象,最大程度地保护加工材料的表面状态。 主要用于校平铝板、不锈钢板、铜板、有色金属板、不同金属复合板,涂、镀、磨工艺金属板等对板表面要求 较高的板材。校平辊受力分布均匀,结构刚性好,工作辊挠曲变形小,校平精度高。

可另外选用自动压下数控系统及典型工件参数存储专家系统。 | |

| Features: |

This machine is a upgrade machine of 4-high level machine. Add one row middle rollers between upper/ lower level rollers and support rollers, and forming each 3-high of upper and lower, total 6-high group rollers. With the transition of middle rollers, the supporting force of the supporting rollers will not act on the working rollers directly, and protect the material surface situation. This machine is mainly used to level aluminum sheet, stainless sheet, copper sheet, nonferrous, compound, printed, plated, polished metal sheet etc., which have high requirements of the surface during processing. The working rollers whose force is equally-distributed have good rigidity, high accuracy of leveling and almost no deflection deformation.

Can choose optional automatcal pressing-system and work piece which is kept in system. | |

|

|

|

| 主要技术参数 Specifications |

| 项目 Name |

单位 Unit |

可选择范围 Optional range |

| 加工板厚 Plate thickness |

mm |

0.3-1.5 0.4-2.0 0.5-3.0 0.6-4.0 |

| 标准板宽 Standard width |

mm |

800 1000 1300 1600 2000 |

| 校平辊数 Level rollers number |

pcs |

17-23 |

| 校平辊直径 Level rollers dia. |

mm |

45-75 |

| 中间辊数 Middle rollers number |

pcs |

19-25 |

| 支撑辊组数 Support rollers number |

Group |

3-5 |

| 校平精度 Leveling precision |

mm/m2 |

0.5-1.0 |

| 校平速度 Leveling speed |

mm/min |

5-25 |

| 主电机功率 Main motor power |

Kw |

15-55 | | |

|

| 本表所列参数,不作为产品检验依据,仅供产品选型参考。如出现与产品实际数据有不一致处,应遵照说明书或双方的技术协议约定。 |

| The data in file not as inspection evidence, just reference for model chosen. If any difference with actual data, please refer to manual or technical agreement by both parties. | |